Associate Spotlight: RAM3D

RAM3D was established in 2012 (as Rapid Advanced Manufacturing Ltd), as a “spin-off” from TiDA (the Titanium Industry Development Association) to focus on growing the commercial opportunities for metal additive manufacturing (i.e. metal 3D printing) in New Zealand. Warwick Downing (RAM3D’s co-founder, CEO and Director) was involved in metal 3D printing initially in 2008, as part of the team that set up the first additive manufacturing (AM) machine in New Zealand.

From the very start, the vision of RAM3D has been about exploring the capabilities of this leading-edge technology and then testing the limits of possibility through design and innovation. All the while, still delivering on high quality and functional parts – for any industry or organisation, that comes to them with a design. With the nature of metal 3D printing being applicable to many industries, and adaptable for fulfilling a wide range of complex requirements, RAM3D’s vision has not changed, because it is change.

RAM3D’s tagline is “Printing the Future” with the main difference between now and 2012 is that they are printing more. They have more machines, are increasing the printing of future-focused parts, for more companies and in more industries – though the aerospace industry continues to be their biggest client sector.

Aerospace New Zealand took some time to sit down with the team from RAM3D to hear more about their story and to ask some questions about their connections to the aerospace industry and community.

Can you talk about the journey from a prototyping focus to full-scale production? What were the key turning points?

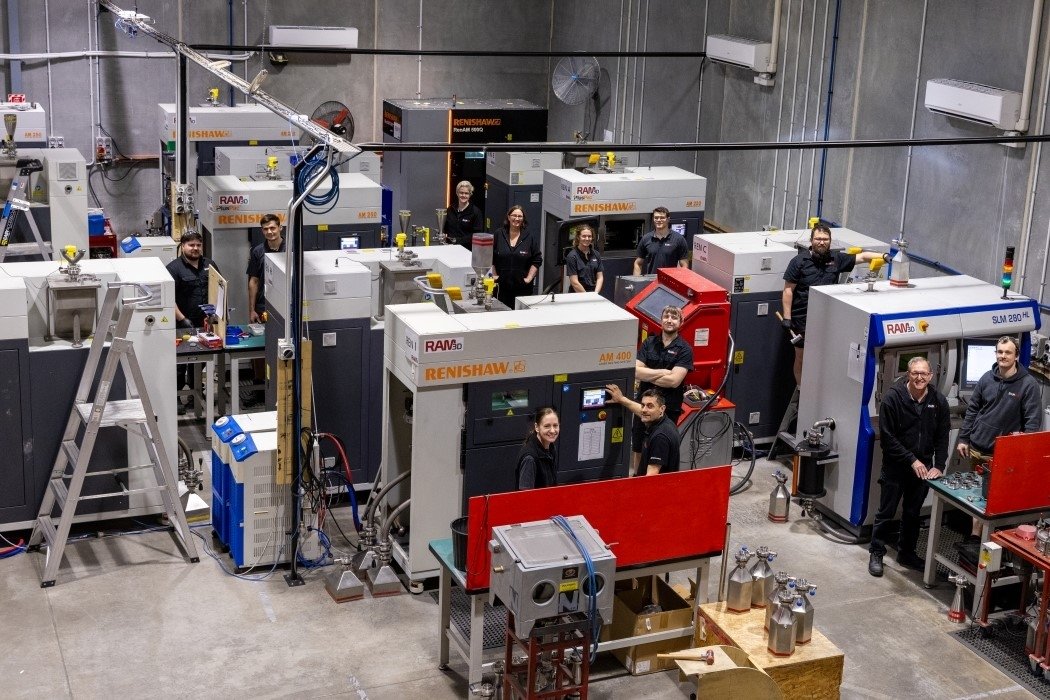

When we moved into our new premises in 2016, we had a total fleet of four additive machines (three Renishaw AM systems and one SLM). We’re up to fifteen Renishaw machines now (including two more just delivered in July 2025). In this journey of continually expanding our production capacity and capabilities, the turning points for us have often come about whenever we have been able to progress our business relationships – with suppliers as well as our customers – to more of a partnership framework.

We partnered with Renishaw on machines, then Autodesk on software, and several others along the way. There is good communication, support, and improvements from both sides meaning our success is also their success. That’s the same for us with our customers – we want your mission-critical parts to succeed just as much as you do. Send us your one-off or prototype part design to start with, and we are going to try to get the best result we can from metal 3D printing it… or else send you back to the drawing board with more guidance on DfAM (Design for Additive Manufacturing). And many of those clients come back with other parts, higher volume production runs, or both. That’s the nature of 3D printing. We’re adaptable for printing whatever is required, whether that be printing one or one hundred – or even printing the hundredth iteration of your design.

And that’s what we do for aerospace: it is not just prototyping, or just full-scale production – we have sixteen machines, regularly printing with our four main materials (titanium, stainless steels 15-5ph & 316, and Inconel), and we might be running production plates and trial parts for the same client all on the same day. The next step in our company journey is already being driven by our customer partnerships and strengthening our in-house capability with installations of new CNC machining centres in the last two years. This will help lessen critical lead-times on certain parts, which makes those clients (and their stakeholders) happy. It’s a win-win.

How do you see metal 3D printing shaping the future of aerospace manufacturing globally, and what role do you see RAM3D playing in that shift?

Metal 3D printing is becoming more and more ‘another tool in the toolbox’ for manufacturing generally, but it’s specifically relevant as a solution for so many of the inherent intricacies of aerospace manufacturing. You can have these complex geometries and structures in your part designs;

- and those parts can also be lightweighted and designed for fuel efficiency;

- and they can be printed in materials that can cope in harsh environments and extreme temperatures and pressures;

- and they can be replicated with repeatability and consistency to achieve qualification and flight certifications.

Prototype parts can be easily revised and then scaled to production. The aerospace industry is naturally very forward-looking and quite competitive, so metal 3D printing can really fit in with that ethos. RAM3D is here, with more than a decade of developing our expertise and improvements in additive manufacturing production technology. We are already working with the space sector and attending aerospace events in Australasia and overseas.

We’re doing our bit, so it is up to space companies to look at their designs and needs, and realise the next step in innovation is to talk to us and get 3D printing working for them, for their spacecraft, launch vehicles, satellites, and components.

RAM3D is based in New Zealand, but aerospace is a highly global industry — how do you connect and collaborate with international aerospace partners and clients?

These days you just have to go where the space companies are – luckily for us they’re still terrestrial-based (for now anyway!) With some invaluable support from New Zealand Trade and Enterprise, we have been attending overseas conferences to connect with clients there, including Small Sat, Space Symposium, and SAT Show in the USA, as well as 2024’s International Astronautical Congress (IAC) in Milan.

Closer to home, we’ve been attending events in Australia and New Zealand, such as the Avalon Airshow and the annual New Zealand Aerospace Summit, along with this year’s IAC hosted in Sydney. Collaboration itself isn’t too difficult (other than the occasional management of time zones), since we’ve been working with the industry for years and know about the requirements for space components. Sometimes the most involved part of the process is patience; projects can take time to get off the ground and, all jokes aside, it can just be a matter of waiting for this person we talked to at that event to get the right part to land on their desk. The right opportunity comes along and they know to come talk to RAM3D about it.

How important is it for the aerospace sector to have local manufacturing options like RAM3D in the Southern Hemisphere — does proximity offer particular advantages?

For the companies we work with who are based here in New Zealand, it’s great to be able to have meetings in-person or have a site visit to understand what we’re each working with and see how we both fit into the other’s operations. And of course, if there’s ever a rush or sudden change of plans, it can be easier to try to accommodate if their parts are dispatching locally rather than around the world.

For international aerospace organisations, we know that we’re part of the New Zealand ‘brand’, a community of aerospace manufacturing and services that they can trust and utilise if they’re looking for quality manufacturing all in one go. New Zealand has strength in manufacturing infrastructure, and the framework to be competitive within a global market.

Could you share an example of a particularly challenging or memorable project?

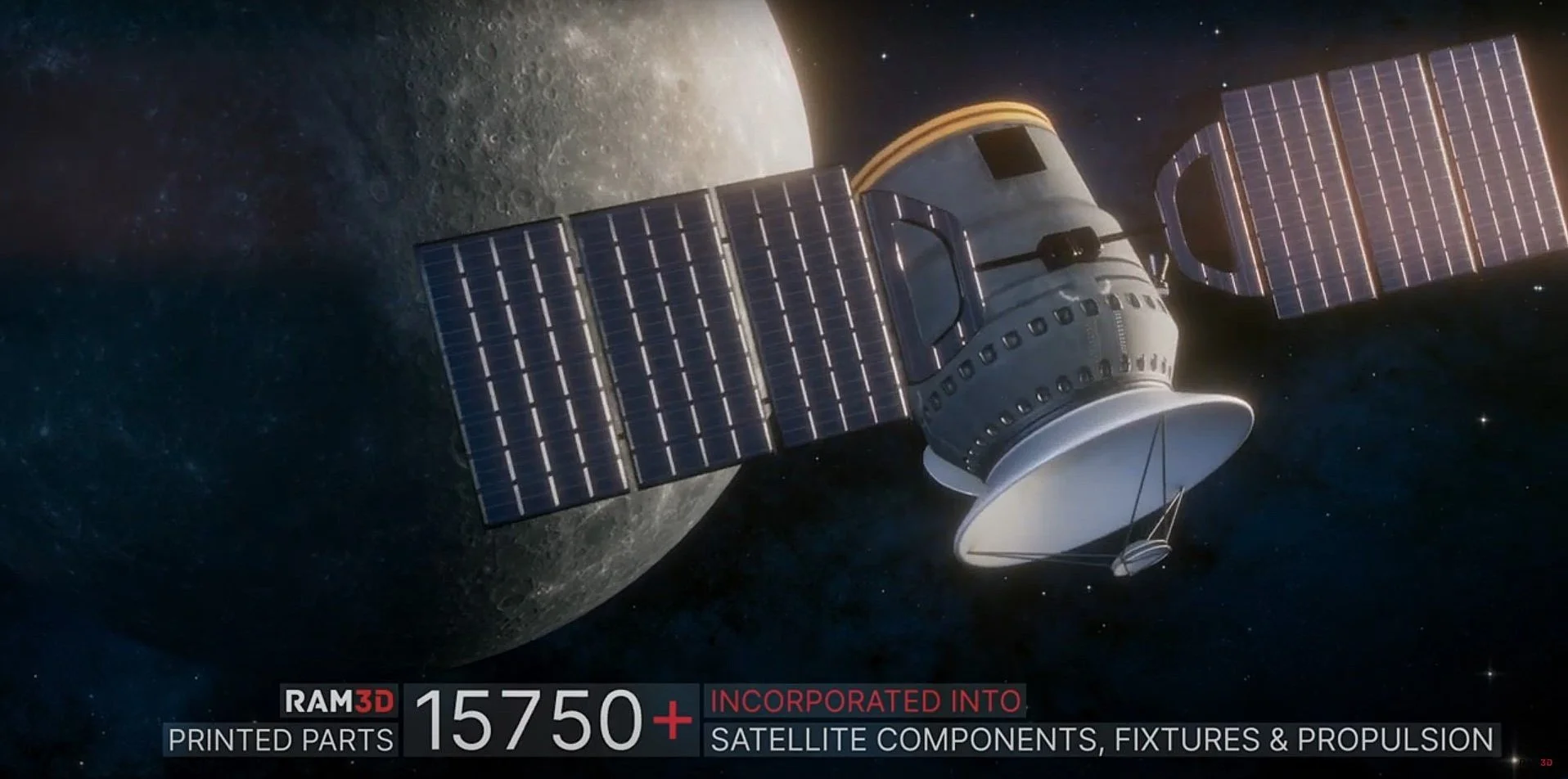

The moon's a pretty big deal, right? 3D printing parts that reached lunar orbit was both a memorable and an intense project. We have quite a few examples over the years of challenging projects that involved making flight-qualified parts for launch propulsion and satellite propulsion. But this project required an intense development programme with weekly manufacturing and testing of new satellite propulsion design iterations, over the course of just a few months in order to meet the launch date.

During that whole process, RAM3D worked with the lead company in the use of a material that generally hadn’t been used for propulsion, and in parallel we further developed our own operations to ensure that the end result would achieve the best possible outcome from the design. The result? The launch met schedule and the satellite propulsion system successfully powered the craft into a lunar orbit. Some might say ‘the sky's the limit’ with what our metal 3D printing can do but for us it's more accurate to say "The sky's no limit"!

What role does RAM3D play in educating the wider industry about additive manufacturing in New Zealand and beyond?

Even as the largest metal 3D printing service provider in the Southern Hemisphere, we still find that education is a core part of developing business relationships. On the global stage, additive manufacturing is no longer a ‘new’ technology, but it still very much has room for further advancements.

Improvements can always be made on the design side of things, which is where we try to help guide our clients in creating a great part that’s also going to print with minimal issues. Research and development continues to be part of our strategy to stay at the forefront of quality manufacturing, so that we can bring this knowledge – about materials, heat treatments, powder handling, laser parameters, etc – to our customers, and to industry trade shows, conferences, and events.

We can tell them that with our metal 3D printing, the parts have the same properties as machined from billet material (i.e. traditional “subtractive” manufacturing), and we have the data and results to prove it. And in a lot of ways, for a lot of parts and components, additive manufacturing can improve a part just by overcoming the constraints of other types of manufacturing processes. At least that’s how we approach it at RAM3D, with a commitment to high quality, which we find is our point of difference for our clients, both in aerospace and other industries, New Zealand and beyond. We really are “Printing the Future” – but every new technology involves a learning curve. We know that, and we’re happy to help our customers learn more to get the best results from it.

What’s next for RAM3D — are there any upcoming expansions, new materials, or sectors you’re excited about?

Over the past year we have added significant capacity and expanded into CNC machining for our clients. We had two more Renishaw AM 400 machines arrive in July, so we’re getting those up and running – probably for adding capacity in Titanium and Stainless Steel 15-5ph. Some R&D with a tooling steel is on the cards. We’re also looking at projects in robotics and the energy sector, industries that are similar to aerospace in that they have some highly specialised and individualised parts, which can really benefit from the advantages of metal additive manufacturing. For something different, we’re also running a CAD contest for New Zealand university students with the winning design receiving a cash prize and the chance to have the design 3D printed for us to show as a display piece at industry events.

What can New Zealand Aerospace Summit 2025 attendees expect from your participation this year?

RAM3D was a Gold Sponsor for the Summit in 2024, so we’re back this year to build on that success. We had invaluable networking opportunities throughout the event, being able to present and premiere our aerospace video, included in this article, and connect with hundreds of attendees as an exhibitor. We are really looking forward to seeing engagement carry over from the International Astronautical Congress (IAC) in Sydney this year through to the Summit as an official adjacent event.

New Zealand Aerospace Summit attendees will have a chance to interact with displays of our 3D printed parts in titanium, stainless steel, and inconel at our exhibitor booth again, and chat with us; as well as getting the chance to hear Warwick Downing speak in a manufacturing and exports focus session on Day 1. RAM3D is always proud to contribute to the future of aerospace, we know that every 50-micron layer we print might just make the next “giant leap for mankind” possible.